In the world of electronics, printed circuit boards (PCBs) serve as the core structural and electrical platform for virtually every device. Among various types of PCBs, rigid PCBs are the most common due to their mechanical stability and cost-effectiveness. This guide to rigid PCB applications explores where rigid PCBs are used, why they’re preferred in many scenarios, and how electronic manufacturing services (EMS) support their development and production.

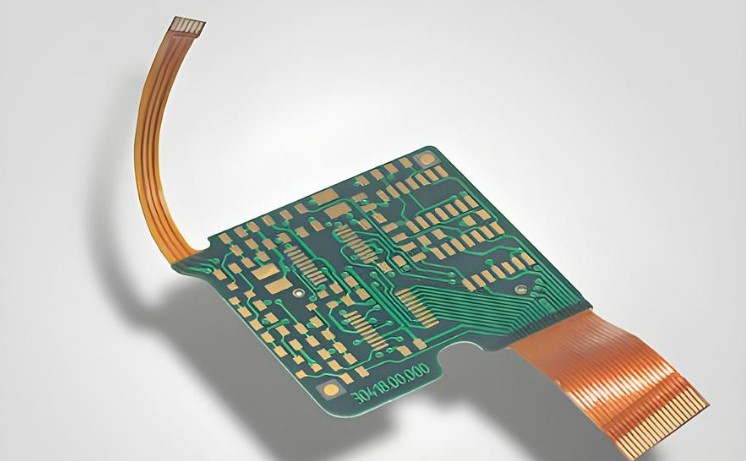

What Is a Rigid PCB?

A rigid PCB is a type of printed circuit board that maintains a fixed, solid shape. Unlike flexible or rigid-flex PCBs, it does not bend or twist. The board is typically made from fiberglass-reinforced epoxy (FR4) or other rigid materials, offering strength and durability for permanent applications.

Rigid PCBs can be single-sided, double-sided, or multilayer, depending on the eeetimes complexity of the circuitry. These boards are commonly found in consumer electronics, industrial equipment, medical devices, and many other sectors.

Key Benefits of Rigid PCBs

Before exploring applications, it’s important to understand why rigid PCBs are widely used:

- Mechanical Strength: They provide a sturdy structure to support components and connectors.

- Ease of Handling: Their inflexible nature simplifies assembly and installation processes.

- Reliability: They offer stable electrical pathways and reduced signal interference.

- Cost-Effective: Compared to flexible PCBs, rigid boards are often cheaper to manufacture in volume.

These advantages make rigid PCBs a practical solution for static electronic environments where flexibility is not required.

Guide to Rigid PCB Applications

Rigid PCBs are foundational in many industries. Here’s a detailed look at where they are used:

- Consumer Electronics

From smartphones to televisions and gaming consoles, rigid PCBs power the essential functions of consumer gadgets. Their rigid structure provides a secure base for microprocessors, memory chips, and connectors. Devices like remote controls, Bluetooth speakers, and smart home gadgets also rely on rigid PCBs for consistent performance.

- Computers and Peripherals

Desktops, laptops, servers, and their accessories use rigid PCBs extensively. The motherboard—the central nervous system of a computer—is a multilayer rigid PCB. Graphic cards, hard drives, and power supplies also integrate rigid boards to ensure stable connections and high-speed data transmission.

- Automotive Electronics

Modern vehicles contain dozens of electronic systems, from infotainment units and GPS modules to engine control units and advanced driver-assistance systems (ADAS). Rigid PCBs are used in many of these applications due to their durability, high temperature tolerance, and compatibility with surface-mount technology.

- Industrial Automation

Rigid PCBs are found in programmable logic controllers (PLCs), motor drives, and control panels across manufacturing environments. Their structural strength is vital in rugged industrial settings where vibrations and environmental stress are common.

- Medical Devices

Diagnostic equipment such as ECG monitors, imaging systems, and infusion pumps use rigid PCBs for reliable performance and long service life. Medical-grade PCBs must adhere to strict safety and cleanliness standards, which EMS providers help maintain through specialized processes.

- Aerospace and Defense

In high-reliability applications such as radar systems, avionics, and satellite communications, rigid PCBs are essential. Their multilayer configurations support dense routing and high-speed signal integrity while resisting thermal and mechanical stress.

- LED Lighting

Rigid PCBs act as the backbone of LED lighting modules in commercial and residential installations. They help maintain consistent electrical output and can be paired with aluminum substrates for better heat dissipation in high-power lighting systems.

The Role of Electronic Manufacturing Services

The design, fabrication, and assembly of rigid PCBs are often handled by specialized electronic manufacturing services (EMS) providers. These companies offer end-to-end solutions that help product developers scale efficiently while maintaining quality.

- Design for Manufacturability (DFM)

EMS providers often assist with DFM reviews to ensure the rigid PCB layout aligns with manufacturing capabilities. This reduces design errors, saves costs, and accelerates time to market.

- Prototyping and Testing

For new products, EMS companies offer quick-turn prototyping and functional testing. This allows engineers to validate designs before committing to large-scale production.

- Component Sourcing

EMS providers typically have established supplier networks to source quality components at competitive rates, reducing the procurement burden for OEMs.

- PCB Fabrication

From single-layer to multilayer rigid boards, EMS partners can fabricate PCBs using industry-standard materials and processes, including surface finishes like ENIG or HASL.

- Assembly and Integration

Surface mount and through-hole technologies are used to mount components precisely onto the board. Some EMS companies also handle complete system integration and enclosure assembly.

- Testing and Quality Assurance

Rigorous inspection processes such as automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT) ensure that each board meets quality standards.

- Logistics and Support

EMS partners often handle packaging, warehousing, and shipping logistics, allowing customers to focus on product development and marketing.

Why EMS Is Critical for Rigid PCB Applications

Whether you’re designing a wearable health monitor or an industrial controller, working with an experienced EMS provider can significantly improve your project’s success. They bring:

- Scalability: From 10 units to 10,000, EMS providers can adapt quickly.

- Speed: Faster lead times mean quicker market entry.

- Compliance: Industry certifications (ISO, IPC, RoHS) ensure product safety and global market compatibility.

- Cost Optimization: Through bulk purchasing and efficient processes, EMS companies help reduce production costs.

Final Thoughts

Rigid PCBs are a cornerstone of modern electronics, offering strength, reliability, and cost efficiency across a broad spectrum of applications. This guide to rigid PCB applications highlights how these boards serve industries ranging from automotive and medical to consumer electronics and industrial automation.

To fully leverage the benefits of rigid PCBs, partnering with a trusted electronic manufacturing services provider is key. From prototyping to final assembly, EMS partners bring the technical expertise, infrastructure, and scalability needed to turn designs into dependable, high-performance products.